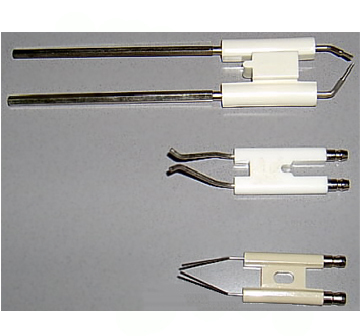

Ignition Electrodes & Ionization Probe

Ignition Electrodes & Ionization Probe Specification

- Wire Length

- Standard/Customizable

- Set Contains

- 1 Ignition Electrode/Ionization Probe

- Current

- Standard Operating Current

- Control Type

- Electronic

- Color

- White and Silver

- Operating Type

- Continuous Duty

- Sensor Type

- Ionization Sensing

- Phase

- Single Phase

- Vehicle Model

- Applicable to Gas Burners and Boilers

- Start Method

- Automatic/Electric Start

- Mounting Type

- Threaded/Flanged

- Ignition Type

- Electric Spark Ignition

- Usage & Applications

- Used for ignition and flame detection in industrial gas burners, boilers, and heating systems

- Connector Type

- Male Connector

- Type

- Ignition Electrodes & Ionization Probe

- Car Make

- Universal

- OE Number

- Standard Replacement

- Material

- Ceramic and Stainless Steel

- Size

- Customized As Per Requirement

- Application Area

- Burner Control Systems

- Insulation Resistance

- >= 500 M

- Electrode Gap

- 2.5 mm (Adjustable)

- Voltage Rating

- 230V AC

- Durability

- High Durability, Reliable Operation

- Flame Detection Range

- Up to 20 A

- Temperature Resistance

- Up to 1200C

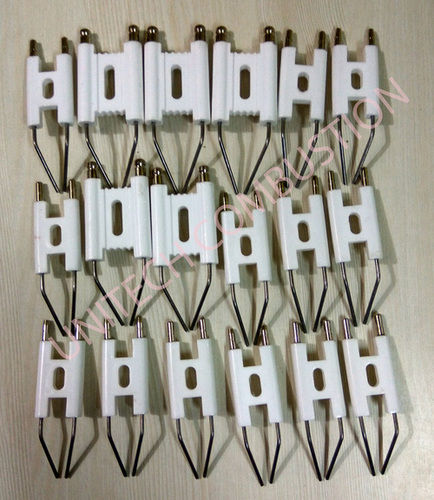

Ignition Electrodes & Ionization Probe Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Uttarakhand, Daman and Diu, Lakshadweep, Gujarat, Delhi, North India, Kerala, Central India, Odisha, Chhattisgarh, All India

About Ignition Electrodes & Ionization Probe

Backed by affluent industry experience and knowledge, we are offering our clients better quality gamut of Ignition Electrodes & Ionization Probe which is used as high voltage resistance. The offered electrode is manufactured by our highly trained team of engineers using premium quality components as per the set industrial quality standards. Also, the provided electrode is vigorously checked by our quality inspectors. Ignition Electrodes & Ionization Probe is made available in different specifications.

Features:

-

High operational fluency

-

Robustly construction

-

Precisely engineered

-

Negligible maintenance

Ignition Electrodes & Ionization Probe

This Ignition Electrodes & Ionization Probe which are used in various applications and offers efficient functionality. Our talented and qualified workers use strict checking and completely ensure before sending it to the clients. These are available with unanimous quality and highly used by our clients. These electrodes are durable in quality and facilitate reliable performance.

Product details

| Frequency | 50/60 Hz |

| Type | Ignition Electrode |

| Voltage | 230 V |

Advanced Performance and Durability

Our ignition electrodes and ionization probes are built to withstand extreme temperatures and harsh operating conditions. With an impressive temperature resistance up to 1200C and high insulation resistance, these components ensure dependable performance and extended service life, making them an ideal choice for a wide range of industrial gas burners and heating systems.

Flexible Application and Customization

Designed for universal compatibility, these probes fit various gas burners, boilers, and vehicles, supporting numerous installation and replacement needs. Available in custom sizes, with both threaded and flanged mounting options and adjustable electrode gaps, they offer tailored solutions to meet unique project requirements while maintaining operational safety and efficiency.

FAQs of Ignition Electrodes & Ionization Probe:

Q: How do ignition electrodes and ionization probes operate in burner control systems?

A: Ignition electrodes provide an electric spark to ignite gas burners, while ionization probes detect flame presence by measuring ionization current, ensuring safe continuous burner operation by verifying that a flame is consistently maintained.Q: What are the benefits of using electrodes with high temperature resistance and insulation?

A: The high temperature resistance (up to 1200C) and excellent insulation (500 M) enable these electrodes to function reliably in demanding industrial settings, reducing the risk of failure and extending component lifespan for cost-effective operation.Q: When should ignition electrodes and ionization probes be replaced?

A: Replacement is recommended if there is inconsistent ignition, unreliable flame detection, visible wear, or after a prescribed operational period as specified by the burner or boiler manufacturer, ensuring safety and continual reliable performance.Q: Where can these electrodes and probes be installed?

A: They are designed for universal installation in industrial gas burners and boilers, with mounting options for both threaded and flanged configurations, allowing flexible integration in a wide array of heating equipment and systems.Q: What is the process for adjusting the electrode gap?

A: The electrode gap, initially set at 2.5 mm, can be manually adjusted according to the burner or system manufacturers specifications. Accurate adjustment ensures optimal spark generation and flame detection for the most efficient operation.Q: How does ionization sensing enhance safety in heating systems?

A: Ionization sensing detects whether a burner flame is present. If the flame goes out, the system recognizes the absence of the ionization current and can immediately shut off the gas supply to prevent hazardous conditions, ensuring operational safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ignition Electrode Category

Riello Burner Ignition Electrode

Price Range 500.00 - 1000.00 INR

Minimum Order Quantity : 1 Piece

Usage & Applications : Used in Riello Gas and Oil Burners, Industrial Burners

Ignition Type : Spark Ignition

Start Method : Electric Spark

Mounting Type : Threaded/Mounting Bracket

Ecoflam burner H Type Electrode

Price Range 500.00 - 1000.00 INR

Minimum Order Quantity : 1 Piece

Usage & Applications : Ecoflam Burners, Gas/Oil Burners, Industrial Heating

Ignition Type : Spark Ignition

Start Method : Electronic

Mounting Type : Threaded/Flange

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS