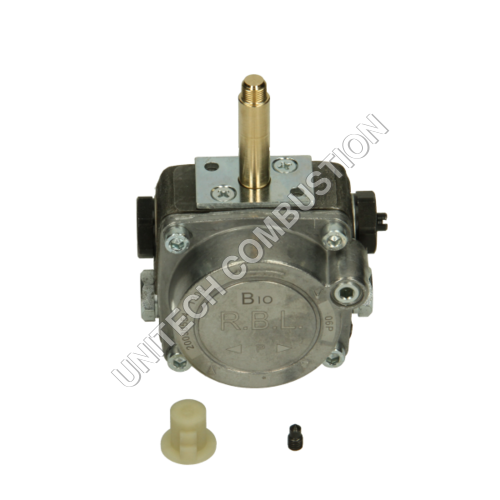

Oil Burner Pump - AS 47 C A

Oil Burner Pump - AS 47 C A Specification

- Type

- Oil Burner Pump

- Power(W)

- 80 W

- OE Number

- AS 47 C A

- Material

- Aluminum Alloy

- Dimension (L*W*H)

- 170 mm x 110 mm x 95 mm

- Motor

- Suitable for Single and Three Phase

- Voltage

- 220 V / 240 V

- Weight

- 1.6 kg

- Spindle

- Precision Steel Spindle

- Control System

- Mechanical

Oil Burner Pump - AS 47 C A Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID)

- Supply Ability

- Piece

- Delivery Time

- ex stock Days

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, South India, North India, East India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Kerala, Uttarakhand, Daman and Diu, Lakshadweep, Uttar Pradesh, Andhra Pradesh, Central India, Odisha, West India, Chhattisgarh, All India

About Oil Burner Pump - AS 47 C A

With an experience of various years, we are engaged in offering durable Magnetic Oil Burner Pump. It is designed and manufactured as per set market quality standards using quality-approved raw materials and modern technology. Widely appreciated for oil and other related applications, this pump is made available in different designs and capacities to meet the wide requirements of clients. Furthermore, we offer this Oil Burner Pump at rock bottom prices to the clients.

Features:

-

Sturdiness

-

Simple construction for ease of maintenance

-

Lower power consumption

-

Optimum performance

Oil Burner Pump - AS 47 C A

Unitech Combustion, Ahmedabad Importer & traders of Suntec oil burner pumps in bulk stock.

we have folowing Suntec oil burner pumps are available

- D 57 A & C

- D67 A &C

- D77 A & C

- AN 47A/C & D,

- AN 67A/B & C,

- AS 47A K/C,

- AL 65C,

- AT2 45A,

- AJ 4AC/CC,

- AJ 6AC/CC/AE,

- E4 NA/NC,

- E6 NB/NC,

- E7 NA/NC 1001, 1069,

- TA-2C,

- TA-3C,

- TA-4,

- TA-5.

Reliable Performance for Industrial Applications

The AS 47 C A Oil Burner Pump is engineered to support high-efficiency operations in industrial oil burners and boiler systems. Its precision steel spindle and single-stage rotary vane design ensure steady flow and optimum pressure handling up to 25 bar. This makes it a trusted solution for demanding environments where operational reliability is essential.

Versatile and Easy to Install

With flange mounting and a 1/8" BSP inlet/outlet, the AS 47 C A seamlessly integrates with most standard burner and boiler systems. Its lightweight aluminum construction, coupled with compatibility for both single and three-phase motors at 220 V/240 V, enables flexible configuration for various industrial needs. This adaptability simplifies installation and ongoing maintenance.

Built for Durability and Safety

Constructed from a robust aluminum alloy and featuring a nitrile rubber shaft seal, the AS 47 C A is designed for longevity and smooth operation within a temperature range up to 60C. The mechanical control system and precision steel spindle further enhance reliability, ensuring safe and consistent fuel delivery in industrial settings.

FAQs of Oil Burner Pump - AS 47 C A:

Q: How do I install the AS 47 C A Oil Burner Pump on a standard boiler system?

A: The AS 47 C A Oil Burner Pump is designed for convenient flange mounting, making installation straightforward on most standard burner and boiler systems. Simply align the flange with the designated port, secure it with suitable bolts, and connect the 1/8" BSP inlet and outlet lines. Ensure that the electrical motor is compatible (single or three-phase at 220 V/240 V) for safe operation.Q: What are the benefits of using a single-stage rotary vane pump in industrial oil burners?

A: Single-stage rotary vane pumps like the AS 47 C A provide consistent fuel flow and stable pressure, which are essential for efficient and safe burner operation. This design also minimizes maintenance needs, as the pump is less prone to clogging and wear, ensuring reliable long-term performance in industrial applications.Q: When should I consider replacing the shaft seal in the AS 47 C A Oil Burner Pump?

A: The nitrile rubber shaft seal in the AS 47 C A pump should be inspected regularly as part of routine maintenance. If you notice oil leaks or reduced efficiency, it is a sign the seal may be worn and should be replaced promptly to prevent further damage and maintain optimal pump performance.Q: Where can the AS 47 C A Oil Burner Pump be used aside from standard industrial burners?

A: While primarily designed for industrial oil burners and boiler systems, the AS 47 C A can also be used in any compatible equipment requiring oil delivery at pressures up to 25 bar and temperatures up to 60C. Its robust construction and versatility make it suitable for a broad range of industrial heating applications.Q: What maintenance process is recommended to ensure long-term performance of this pump?

A: To ensure longevity and optimal efficiency, regularly inspect the pump for signs of wear, oil leaks, or unusual noises. Check the shaft seal, connections, and inlet/outlet filters periodically. Lubricate moving parts as specified in the manual and ensure the pump operates within the stated voltage and speed parameters.Q: How does the material and design of the AS 47 C A contribute to its durability?

A: The pumps aluminum alloy housing provides excellent corrosion resistance, while the precision steel spindle and nitrile rubber shaft seal enhance durability under continuous operation. These quality materials help the pump withstand the rigors of industrial use and extend its service life.Q: What power and voltage specifications are required for the AS 47 C A Oil Burner Pump?

A: The AS 47 C A operates efficiently with a power requirement of 80 W and can be connected to either 220 V or 240 V, supporting both single and three-phase motors. This flexibility ensures compatibility with a wide range of industrial electrical systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Oil Burner Pumps Category

Suntec Fuel Pump E 6 NB

Price Range 9000.00 - 10000.00 INR

Minimum Order Quantity : 1 Piece

Material : Other, Cast Iron

Type : Fuel Pump

Control System : Mechanical

Fuel Oil Pump AJ 4 AC

Minimum Order Quantity : 100 Pieces

Material : SS

Type : Fuel Pump

Control System : Electronic Flow Control

Riello Burner Oil Pump

Price Range 40000.00 - 50000.00 INR

Minimum Order Quantity : 1 Unit

Material : Other, Aluminium

Type : Other, Oil Pump

Control System : Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free