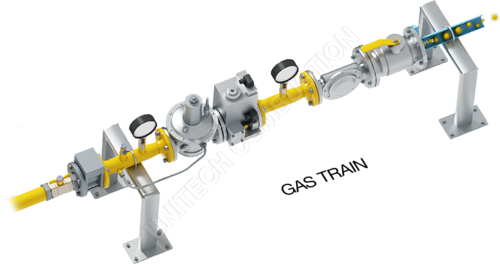

Vanaz Make High Pressure Gas Train DN 25

Vanaz Make High Pressure Gas Train DN 25 Specification

- Control System

- Manual

- Base Material

- Carbon Steel

- Thickness

- 6 mm (Approx)

- Cabinet Material

- Sheet Metal

- Components

- Isolation Valve, Slam Shut Valve, Pressure Regulator, RPD Meter, Safety Relief Valve, Filter

- Protection Class

- Class I

- Connectivity Type

- Flanged Ends

- Protection Level

- IP54

- Cover Material

- Mild Steel/Sheet Metal

- Product Type

- High Pressure Gas Train

- Material

- Carbon Steel

- Surface Finish

- Powder Coated/Painted

- Standard

- IS/BS/DIN

- Surface Color

- Silver/Grey

- Dimension (L*W*H)

- Custom/As per Order

- IP Rating

- Ip54

Vanaz Make High Pressure Gas Train DN 25 Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Payment Terms

- Telegraphic Transfer (T/T)

- Supply Ability

- Piece

- Delivery Time

- Ex Stock Days

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Kerala, Lakshadweep, Haryana, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

About Vanaz Make High Pressure Gas Train DN 25

We are a trustworthy manufacturer and supplier of supreme quality range of Vanaz Make High Pressure Gas Train. The offered product is manufactured under the supervision of our skilled professionals using quality tested components, procured from reliable vendors of the market. This product is used at several industries such as petrochemical, marine, chemical, food processing and oil & gas. We offer this Vanaz Make High Pressure Gas Train as per the requirements of the clients at most economical prices.

Features:

-

Robust construction

-

Long operational life

-

Precisely designed

-

Durability

Precision Engineered Gas Train

This high pressure gas train is meticulously constructed with advanced safety features such as slam shut valves, safety relief valves, and robust isolation. Its carbon steel framework delivers resilience, while components like the RPD Meter and pressure regulator ensure stable performance suited to demanding gas distribution systems.

Customizable and Reliable

Vanaz offers flexibility with custom dimensions and models manufactured to specification. The gas train supports a range of applications thanks to manual control systems, flanged end connectivity, and a selection of high-quality materials. Each assembly is rigorously tested for leakage, meeting top industry standards for performance and dependability.

FAQs of Vanaz Make High Pressure Gas Train DN 25:

Q: How is the Vanaz High Pressure Gas Train DN 25 installed and what are the mounting options?

A: The Vanaz Make High Pressure Gas Train DN 25 can be installed using either floor or skid mounting solutions, depending on site requirements. It features flanged ends for straightforward connection to existing gas pipelines, and dimensions can be customized as per your order.Q: What is the primary usage of this gas train and in what environments is it most suitable?

A: This gas train is primarily used in industrial and commercial gas distribution systems where high pressure regulation and safe handling are essential. It is ideal for environments requiring reliable gas flow, such as manufacturing plants or large-scale facilities, particularly where strict safety standards are observed.Q: What benefits does the adjustable outlet pressure range offer?

A: The adjustable outlet pressure range (0.02 2 bar) gives operators the flexibility to fine-tune gas flow according to process demands, ensuring optimal performance and safety for a variety of end-use applications.Q: When should this model be selected over other gas trains?

A: This particular model should be chosen when there is a need for high inlet pressure capability (up to 17 bar), moderate outlet pressure control, and a flow rate as high as 100 Nm3/hr, especially if custom dimensions, proven leakage testing, and strong protection ratings are required.Q: How does the gas train ensure safety during operation?

A: Safety is enforced through components such as isolation vales, slam shut valves, safety relief valves, and a fully enclosed, IP54-rated cabinet. Additionally, every unit undergoes 100% leakage testing before dispatch to minimize operational risks.Q: What maintenance process is recommended for the Vanaz DN 25 Gas Train?

A: Regular inspections of the valves, filters, and regulators, along with periodic leak testing, are recommended to maintain peak performance. Cleaning and occasional repainting may be necessary, depending on environmental exposure, to preserve the surface finish and integrity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Gas Train And Components Category

Madas Make High Pressure Gas Train DN 50

Price 50000-200000 INR / Set

Minimum Order Quantity : 1 Set

Rated Voltage : 230 Volt (V)

Frequency (MHz) : 5060 Hertz (HZ)

Material : Other

Product Type : Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS