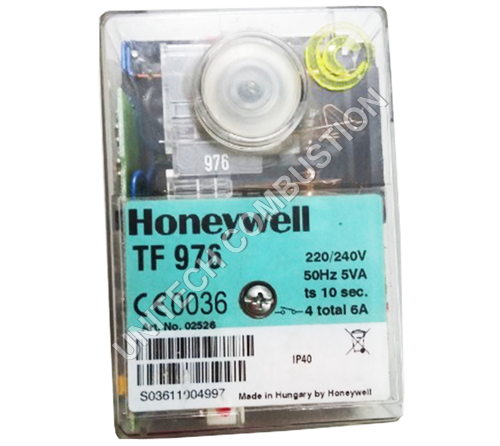

Sequence controller TFI 976

Sequence controller TFI 976 Specification

- Connection

- Screw terminals

- Pressure

- Up to 20 bar

- Accuracy

- 1% of full scale

- Function

- Automatic sequence controller for burner operations

- Size

- 96 mm x 96 mm

- Control Inputs

- Start/Stop push button

- Weight

- Approx. 300 grams

- Timing Range

- 1 99 seconds adjustable

- Display

- LED

- Power Supply

- 230 V AC, 50 Hz

- Ambient Temperature

- 0C to 55C

- Enclosure

- ABS plastic, IP54 rating

- Output

- Relay output (potential free)

- Indication

- Status and fault indication

- Mounting

- Panel mounting

Sequence controller TFI 976 Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 15 Days

- Main Domestic Market

- Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Himachal Pradesh, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Nagaland, Odisha, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Dadra and Nagar Haveli, Lakshadweep, Delhi, Gujarat, Central India, West India, Chhattisgarh, All India

About Sequence controller TFI 976

Our core business lies in meeting customers diverse needs and for this we are indulged in offering the outstanding quality Honeywell Sequence Controller. The offered controller is manufactured using pristine quality components and advanced technology under the supervision of our experienced team of professionals in compliance with set market quality standards. This controller is used in annealing furnace, heat treatment furnace, steam boiler and so on. Further, this Honeywell Sequence Controller is available at affordable prices.

Features:

-

Precisely engineered

-

Strong construction

-

Smooth operation

-

Simple to operate

Reliable Sequence Control for Burners

The TFI 976 is engineered for automatic control of burner operations in industrial settings. It manages and sequences various burner functions for enhanced safety and efficiency, with accurate timing and potential-free relay outputs. Status and fault indications on the LED display help operators maintain seamless operations and promptly identify issues.

Durable and Easy to Install

Constructed from robust ABS plastic with an IP54 rating, the TFI 976 withstands dust and water splashes, making it suitable for diverse environments. Its panel mounting design and screw terminal connections ensure straightforward installation, supporting both new setups and retrofit applications.

Precise and Adjustable Timing

With an adjustable timing range from 1 to 99 seconds and an impressive 1% accuracy, the TFI 976 allows flexible control over burner sequences. Operators can fine-tune process timing to suit specific application requirements, supporting consistent performance and operational safety.

FAQs of Sequence controller TFI 976:

Q: How does the Sequence Controller TFI 976 enhance burner operation safety?

A: The TFI 976 provides automatic sequencing for burners, reducing human error and ensuring safe start-up and shutdown cycles. Its status and fault indications enable quick identification of operational issues, while accurate timing assists in maintaining reliable burner performance.Q: What is the process for adjusting the timing on the TFI 976?

A: The timing can be easily adjusted between 1 and 99 seconds using the LED display interface. This allows operators to customize the operation cycle according to the requirements of the application, providing flexibility in burner sequencing.Q: When should the TFI 976 sequence controller be used?

A: The controller is ideally used in industrial environments where controlled sequencing of burner operations is crucial. It is suitable for new installations, upgrades, or retrofitting of burner management systems needing precise, automated control.Q: Where can the TFI 976 be installed, considering its enclosure and rating?

A: With its ABS plastic enclosure and IP54 rating, the TFI 976 is appropriate for indoor panel mounting in areas that may encounter dust or occasional water splashes. It is not intended for outdoor or highly corrosive environments without additional protection.Q: What are the usage benefits of the TFI 976s potential-free relay outputs?

A: The potential-free relay outputs enhance system versatility by safely interfacing with various burner components and external devices without electrical interference, providing flexibility and safe integration within automation setups.Q: How does the status and fault indication system improve operation?

A: The integrated status and fault indication via the LED display allows operators to instantly monitor operational conditions and detect faults, enabling timely maintenance and minimizing downtime for burner systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sequence Controllers Category

RIELLO RMG 88.62A2 BURNER CONTROL

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : Standard compact module

Function : Burner control box for supervision of gas and oil burners

Pressure : Suitable for standard combustion chamber pressures

Accuracy : Reliable flame detection and safety control

Indian Gas Burner sequence Controller

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : Compact design, approx. 120mm x 80mm x 50mm

Function : Sequencing and safe ignition of Indian gas burners

Accuracy : High response time for reliable gas burner operation

Burner Controller LMV 51

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : Compact design suitable for integrated mounting

Pressure : Suitable for low to medium gas pressure systems

Accuracy : High reliability and precise flame monitoring

Siemens Controller LFL 1.322

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : Compact, DIN rail or base mounting.

Function : Automatic burner control for oil/gas burners with or without fan in intermittent operation.

Pressure : Maximum permissible pressure: as per relevant burner requirements.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free