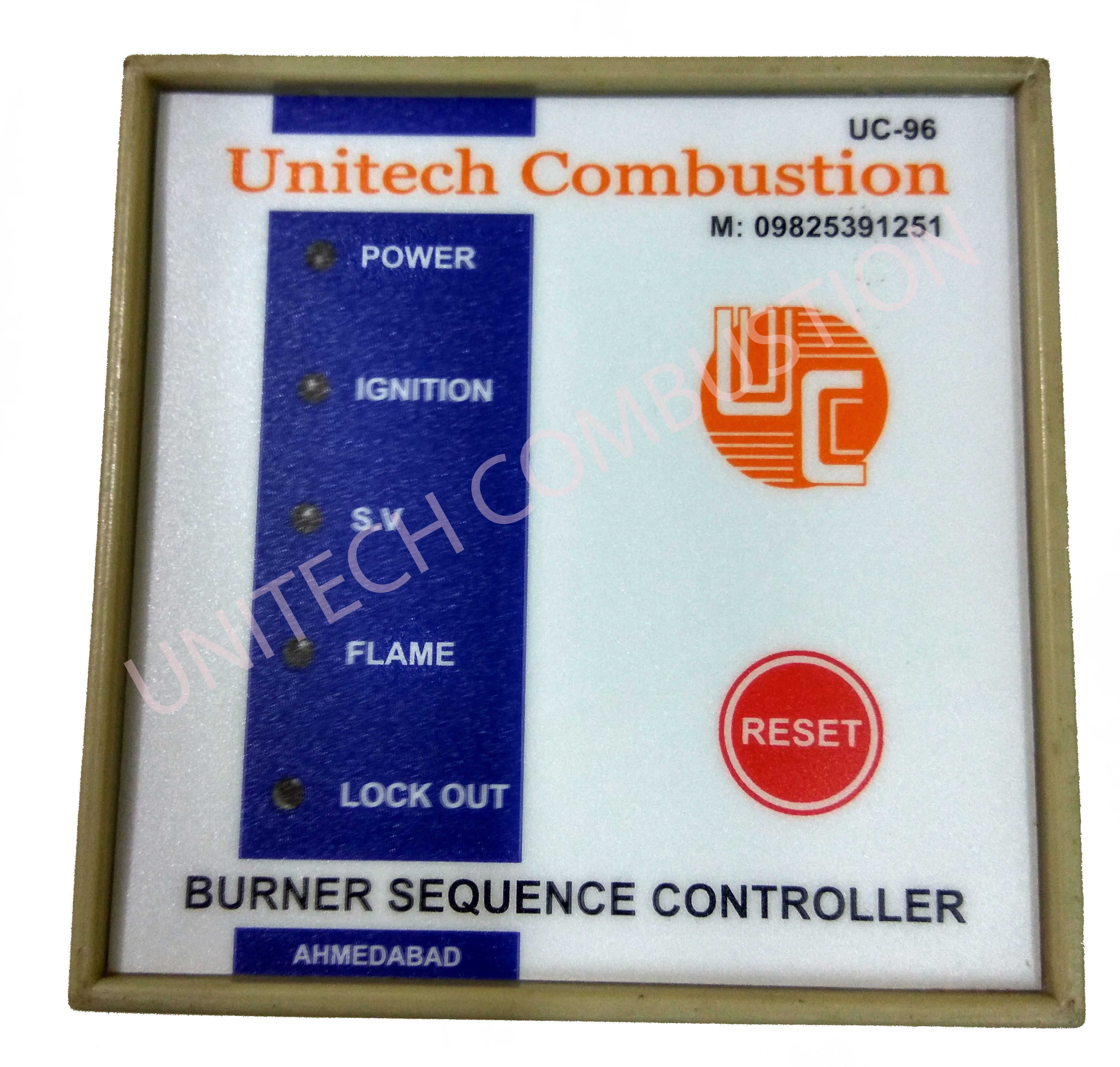

Indian Gas Burner sequence Controller

Indian Gas Burner sequence Controller Specification

- Accuracy

- High response time for reliable gas burner operation

- Function

- Sequencing and safe ignition of Indian gas burners

- Size

- Compact design, approx. 120mm x 80mm x 50mm

- Operating Voltage

- 230V AC, 50/60 Hz

- Control Type

- Microprocessor based automatic sequence control

- Reset Type

- Manual and automatic reset options

- Display

- LED indicators for sequence status and fault

- Mounting

- Panel or surface mounting

- Flame Detection

- Integrated flame sensor compatibility

Indian Gas Burner sequence Controller Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- AHMEDABAD

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 15 Days

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Pondicherry, Nagaland, Daman and Diu, South India, Central India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttarakhand, West Bengal, Lakshadweep, Uttar Pradesh, Karnataka, North India, Andhra Pradesh, Kerala, Odisha, Chhattisgarh, All India

About Indian Gas Burner sequence Controller

We started our business in the year 2004 with an aim to provide best quality Indian Gas Burner sequence Controller. For the manufacturing of this controller, our technocrats use quality tested components and pioneering technology under the stern observation of deft technocrats in sync with the defined quality standards. Sternly examined on several parameters, the offered controller is used in oil burners, pipe burner, hot air burner glass oven and many more. This Indian Gas Burner sequence Controller is available in varied specifications as per the application requirements of customers at reasonable rates.

Features:

-

Easy to operate

-

Sturdy construction

-

Ruggedness

-

Perfect finish

Advanced Microprocessor Control

The sequence controller incorporates a sophisticated microprocessor, enabling automatic sequencing and safe ignition of gas burners. This ensures optimal performance, enhanced safety, and reduced risk of operational errors.

Versatile Installation Options

Designed with flexibility in mind, the controller can easily be mounted on either panels or surfaces. Its compact dimensions allow for quick integration into existing setups without consuming excessive space.

User-Friendly Indication and Reset

LED indicators provide real-time updates on sequence status and faults. Combined with manual and automatic reset options, users can monitor and manage the device effortlessly, ensuring uninterrupted burner operation.

FAQs of Indian Gas Burner sequence Controller:

Q: How does the microprocessor-based automatic sequence control work in this gas burner controller?

A: The automatic sequence control uses a microprocessor to manage ignition, monitor the flame through integrated sensors, and execute pre-set safety protocols. This ensures safe operation of the burner and rapid response to any fault conditions.Q: What are the benefits of using LED indicators on the sequence controller?

A: LED indicators provide clear, visual feedback on the operating sequence and alert users to any faults. This enables quick diagnosis and maintenance, reducing downtime and improving safety.Q: When should the manual or automatic reset option be used on the controller?

A: Manual reset is useful after addressing a fault or during maintenance, allowing operators to restart the system safely. Automatic reset is ideal for minor or transient issues, as it enables seamless operation without user intervention.Q: Where can this gas burner sequence controller be installed?

A: The controller is designed for panel or surface mounting, making it suitable for various industrial or commercial settings where reliable gas burner sequencing and safety are required.Q: What is the process for integrating the controller with a gas burner system?

A: Integration involves wiring the controller to the gas burner, connecting an appropriate flame sensor, and mounting the device to a panel or surface. Upon setup, the controllers microprocessor automates and monitors the ignition sequence.Q: How does the compact design benefit system installation?

A: Its small footprint (approximately 120mm x 80mm x 50mm) allows for easy installation, even in space-constrained control panels or machinery, streamlining system integration and maintenance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sequence Controllers Category

Krom Schorder Sequence Controller IFD 258-10/1W

Minimum Order Quantity : 1 , , Unit

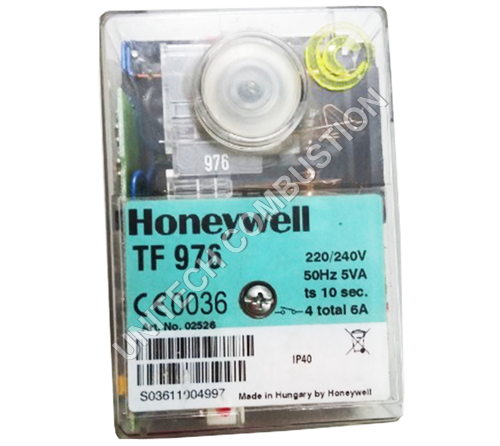

Sequence controller TFI 976

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : 96 mm x 96 mm

Accuracy : 1% of full scale

Pressure : Up to 20 bar

Function : Automatic sequence controller for burner operations

Siemens Controller LFL 1.322

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : Compact, DIN rail or base mounting.

Pressure : Maximum permissible pressure: as per relevant burner requirements.

Function : Automatic burner control for oil/gas burners with or without fan in intermittent operation.

Sequence Controller LAL 3.25

Price Range 2000.00 - 5000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Size : 96 mm x 96 mm x 112 mm (approx.)

Accuracy : High switching and timing accuracy

Pressure : Up to 1 bar

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free